The Ultimate Guide to LED Floodlight Production: From Chip to Shipment

Feb 09,2025 | JD-SmartLighting

Have you ever wondered how high-quality LED floodlights are produced on a large scale? From tiny LED chips to powerful industrial lighting, the production process involves advanced automation, precision engineering, and rigorous quality control.

In this article, JD-Smartlighting will take you inside a modern LED floodlight factory, showcasing how SMT automation, rigorous testing, and efficient warehousing ensure top-tier LED floodlight quality. Whether you’re a B2B distributor, industrial lighting supplier, or facility manager, understanding LED production helps you make informed procurement decisions.

1. The LED Floodlight Manufacturing Process: A Step-by-Step Guide

1.1 Chip Manufacturing – The Core of LED Performance

At the heart of every LED floodlight lies the LED chip, responsible for brightness, efficiency, and longevity. The production process involves:

•Wafer Processing – Cutting semiconductor materials into ultra-thin wafers.

•Phosphor Coating – Applying phosphor to achieve different light temperatures.

•Encapsulation – Protecting the LED chip for durability.

1.2 SMT (Surface Mount Technology) – Automated LED Placement

The SMT process is crucial in assembling LED floodlights efficiently. This high-speed, automated method precisely places LED chips onto printed circuit boards (PCBs), reducing errors and increasing production speed.

SMT Process Breakdown:

1.Solder Paste Application – A thin layer of conductive solder is spread onto the PCB.

2.High-Speed LED Chip Placement – Pick-and-place machines position thousands of LED chips per hour.

3.Reflow Soldering – The PCB is heated to secure the LED components permanently.

Why is SMT crucial for LED floodlights?

•Higher Precision – Reduces manual errors and improves product consistency.

•Increased Production Speed – SMT lines can produce thousands of LED floodlights per day.

•Better Heat Management – Ensures LED floodlights operate at optimal efficiency.

1.3 Assembly & Testing – Ensuring High-Quality LED Floodlights

Once the LED modules are assembled, they undergo rigorous testing to ensure durability and performance.

Key Testing Procedures:

•Thermal Resistance Testing – Evaluating heat dissipation efficiency.

•Luminous Flux Measurement – Ensuring brightness meets industry standards.

•IP65/IP66 Waterproof Testing – Confirming weather resistance for outdoor use.

•Aging Test (Burn-In) – Running LED floodlights for 24-48 hours to detect defects.

Why B2B Buyers Care About Rigorous Testing

B2B buyers, especially in the industrial, commercial, and sports lighting sectors, need floodlights that offer:

•Long lifespan (50,000+ hours)

•Consistent lumen output

•Reliable performance in harsh environments

2. Smart Warehousing & Global Supply Chain Management

Efficient warehousing and supply chain management are key factors in LED floodlight production. Our automated warehouse ensures:

•Faster order fulfillment – 48-hour shipment for bulk orders.

•Real-time inventory tracking – Prevents supply chain disruptions.

•Optimized logistics – Seamless delivery across Europe, the UK, and North America.

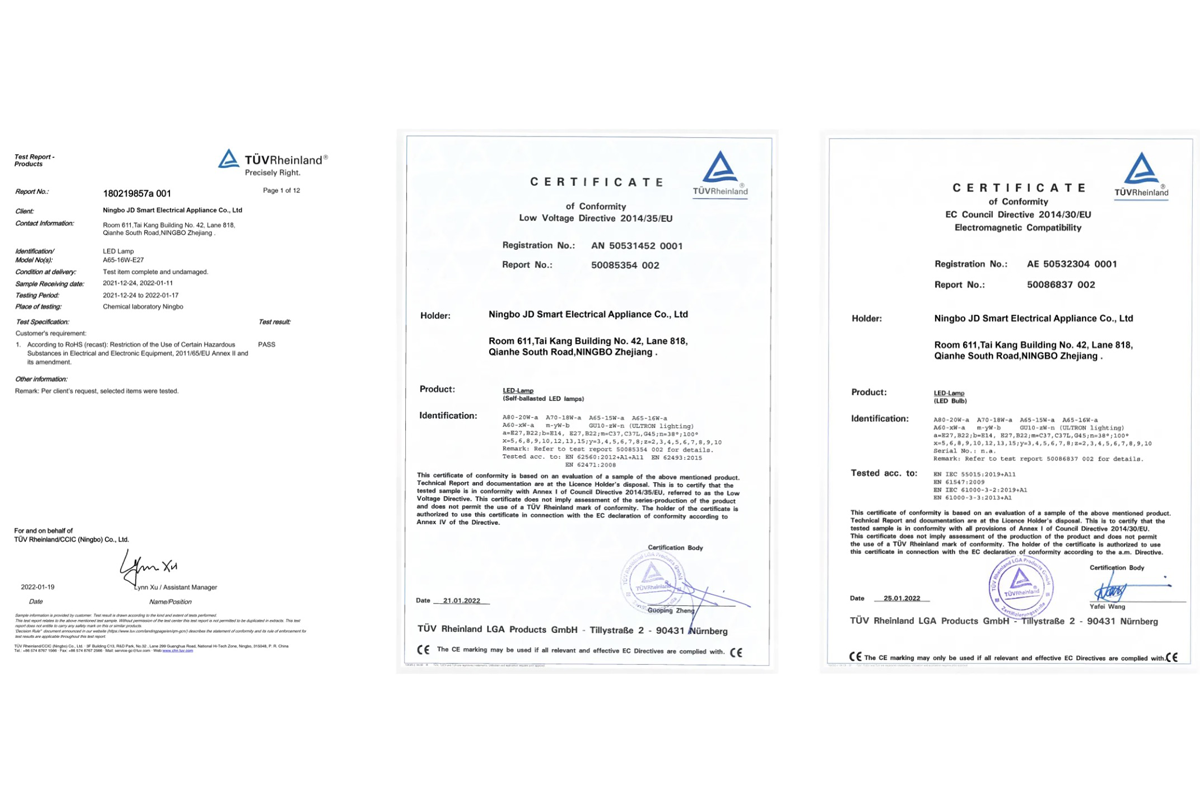

3. Certifications & Compliance: Meeting Global Standards

To ensure LED floodlights meet international safety and performance standards, our production process complies with:

•ISO 9001 – Quality Management System

•CE & RoHS – European Market Compliance

•UL Certification – North American Safety Standards

•IK10 & IP66 Ratings – Durability & Waterproof Performance

Why These Certifications Matter for B2B Buyers?

•Retailers & Distributors need certified LED floodlights for legal market entry.

•Contractors & Installers demand reliable, safety-approved lighting solutions.

•Government & Large-Scale Buyers require environmental & efficiency compliance.

4. Why Choose Our LED Floodlights?

•Cutting-edge SMT production line – High efficiency & precision manufacturing.

•Advanced thermal management – Longer LED lifespan & improved performance.

•Industry-leading warranty – 3-5 year warranty on all LED floodlights.

•Custom solutions for B2B orders – Tailored specifications for wholesalers & large projects.

Need high-quality LED floodlights for your business?

Contact us now for a free quote!

5. Conclusion

From chip manufacturing to SMT automation, from rigorous testing to smart warehousing, JD-Smartlighting's LED floodlight production process ensures reliability, efficiency, and top-tier performance.

Looking for a reliable LED floodlight supplier? We offer:

•Bulk wholesale pricing

•Fast European distribution

•Customization options for large projects

Let’s discuss your LED floodlighting needs today!

Call: +86-173 0703 3680 | Email: nancy@jd-smartlighting.com

Supply Chain Challenges & Solutions

•Raw Material Shortages? We maintain bulk stock of LED chips and aluminum housings.

•Shipping Delays? Our EU-based fulfillment centers ensure fast local distribution. 45-day bulk order lead time.

•Quality Concerns? Every floodlight batch is tested before shipment.